For eleven straight years, AJ Veneklasen has been granted a place on the list of “Best and Brightest Companies” to work for in West Michigan. This repeating accomplishment is the result of our team’s creativity, hard work, and passion for supporting each other – as well as our belief that company growth happens when we invest in the skills and well-being of our people.

We live that philosophy in many ways. In our industry, a great workplace is defined differently depending upon an employee’s role. For our team in the office, it means a healthy and inspiring environment where people feel comfortable, appreciated, fulfilled, and supported in their work. For our teams working on jobsites, add the critical needs of safety, team comradery, and skills development to that list. For all of us, being part of a cohesive team is key to enjoying our work and feeling valued, which is why all our programs seek to unite our team around a shared purpose.

Here’s a few of the AJV programs that have contributed to winning the Best & Brightest Companies honor:

Fuel the Field – a monthly surprise delivery of food and fun to the crew at one of our jobsites. The event is coordinated by our office staff who enjoy visiting their teammates on jobsites as much as the crew enjoys their surprise lunch.

Fuel the Field – a monthly surprise delivery of food and fun to the crew at one of our jobsites. The event is coordinated by our office staff who enjoy visiting their teammates on jobsites as much as the crew enjoys their surprise lunch.

Volunteer Day – our entire team is invited to be hands-on with a local non-profit organization to make someone’s day brighter or to further a philanthropic mission. Participating isn’t mandatory, but each year, we have 100% participation in support of organizations like Special Olympics and Habitat for Humanity.

Culture Committee Events – a series of social events organized by the AJV Culture Committee brings our team and their family members together several times each year. Even during a pandemic when we had to meet virtually, events like Holiday parties, chili cookoffs, and summer BBQ events keep our team smiling and feeling connected.

Toolbox Talk – a weekly gathering of our field crew to collaborate around how to use new tools and equipment safely and productively.Being honored every year for over a decade puts extra pressure on us to continue to perform so we are constantly re-inventing our programs – plus – after winning the Best & Brightest award for 11 straight years we really don’t want the streak to end. Every year we get more creative to improve our performance over the previous year.

About the Award

The mission of The National Association for Business Resources – founders of the Best & Brightest program – is to connect, educate, and empower businesses. According to their website, “Through the Best and Brightest programs, the National Association for Business Resources provides specialized business services, education, and resources for businesses throughout the United States.” From our point of view, the incentive offered by the Best & Brightest program is one of the things that motivates our commitment to a healthy and supportive workplace. However, our biggest incentive is to witness a happy and satisfied team advancing their careers by using their talents and gifts to help our company be the best it can be.

It's not just lumber that's on a bumpy ride.

Like the broader economy, the construction industry commodities market is a delicate balance that's been thrown off by raw material disruptions, transportation challenges, and labor shortages caused by the 2020 pandemic - followed by increasing demand in 2021. According to a report from forconstructionpros.com, commercial construction is projected to grow by 6% this year and another 10% in 2022. This new pipeline of project starts is causing materials vendors to quote not just higher prices, but also long timelines to deliver materials to job sites.Price and schedule benefits for projects breaking ground in 2021.

Projects that are currently underway or soon to break ground are moving ahead with few issues, but projects that will start in 2022 are vulnerable to the looming price and schedule impacts. The ongoing material volatility is resulting in uneven demand that is on the verge of impacting construction schedules, causing project gaps that our trade partners are actively looking to fill. From our point of view, a trend toward pricing opportunities from trade partners will begin this fall as high commodity prices begin to moderate or drop and contractor backlogs shorten. This market environment points to better materials pricing starting this fall, followed by the potential for steep increases in demand in 2022. The other factor we're watching is the potential for expanded U.S. infrastructure projects in 2022 that may tighten the materials market further. Bottom line - if your business plans include expanding or renovating your facilities - now is the time to get started. Projects with design and planning work underway this summer may benefit from a fall 2021 market "sweet spot". This climate calls for a great GC, who is a committed partner, and a knowledgeable consultant.

This climate calls for a great GC, who is a committed partner, and a knowledgeable consultant.

As an experienced, full-service general contractor, the aj Veneklasen team can advise you on all the nuances of this complicated market and how it may positively or negatively impact your particular project. Our VENEBUILT process is designed to help customers navigate this kind of complexity, bringing the right partners, design, and construction management experts together to quickly and confidently guide you.

Let's talk soon about when and how to approach your next project.

Located at 335 Center Street, South Haven, MI, 42N Naturals has officially had their grand opening and ribbon-cutting ceremony. 42N Naturals offers handmade products by the lake and creates handmade soaps, lip balms and body scrubs. They use Midwest sourced ingredients with sustainable packaging practices.

This store is located on the retail floor of the South Haven Center mixed-use building, developed by Veneklasen Construction. With a four-week turnaround, Veneklasen Construction built out the retail space for 42N, making it the perfect spot for them to create their handmade products. This location will also be used to make and source their Saugatuck store. The ribbon-cutting ceremony on April 14, 2022, kicked off the grand opening of this store where The South Haven Chamber of Commerce members all came to offer their support of the launch.View the Grand Opening Coverage

|

|

|

Veneklasen Construction’s new metal building for Mobile Defenders was honored with a Hall of Fame award from metal building materials supplier Varco Pruden Builders. The 86,000 sq ft project won top honors in the office building category. The eduParts brand also operates from the property.

Veneklasen Construction’s new metal building for Mobile Defenders was honored with a Hall of Fame award from metal building materials supplier Varco Pruden Builders. The 86,000 sq ft project won top honors in the office building category. The eduParts brand also operates from the property.

The annual Varco Pruden Hall of Fame recognizes top architectural building projects from authorized Varco Pruden builders. Veneklasen Construction is one of nearly 1000 authorized Varco Pruden builders in North America. According to varcopruden.com “Winning projects exemplify innovation and excellence using Varco Pruden building systems that showcase exceptional architectural designs, efficiencies, and desired end-use.”

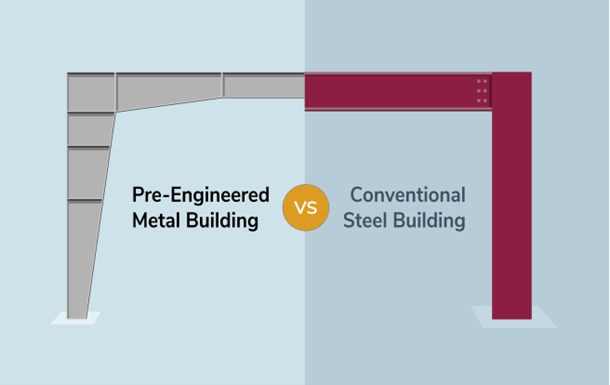

The pre-engineered metal building solution

A pre-engineered metal building is more cost-effective and faster to build than conventional steel construction, making it the ideal choice for this project. Varco Pruden structural materials combined with custom finishes and masonry accents to deliver all the function the client needed. The welcoming aesthetic they desired was also achieved. The entire project took 8 months from ground-breaking to move-in despite winter weather delays and supply chain issues.Veneklasen Construction's pre-engineered metal building capability has been developed over 45 years in the business. Today’s self-managed steel erection teams, state-of-the-art equipment, and vast experience make Veneklasen among the most capable steel building contractors in the Midwest. CEO Chris Veneklasen shares what this award means to him and his team, “Being acknowledged for the quality of our PEMB capabilities feels really good. It’s a nod to the steel construction expertise we’ve worked hard to develop, and it highlights the powerful solutions we can bring to our customers as a Varco Pruden builder. Most importantly, it’s a well-deserved pat on the back for our project management and steel teams.”

Thriving today, room to grow tomorrow

The new building features 12,000 sq ft of office space, 27,000 sq ft of ancillary warehouse space, and 48,000 sq ft of additional space for up to 3 future tenants. PURE Architects of Grand Rapids Michigan designed the low-maintenance, high-function metal building to serve the tech client’s immediate and future growth needs.

The new building features 12,000 sq ft of office space, 27,000 sq ft of ancillary warehouse space, and 48,000 sq ft of additional space for up to 3 future tenants. PURE Architects of Grand Rapids Michigan designed the low-maintenance, high-function metal building to serve the tech client’s immediate and future growth needs.

Inside, a mix of enclosed and open-plan offices are supported with amenities including flex areas for collaborative work, a gym, breakrooms, and kitchen. The office space, which can accommodate up to 95 team members, was home to 65 employees at its opening in October 2022. Office areas feature energetic colors inspired by the company’s brands. Finishes on counters and furniture offer both durability and home-like comfort. Specialized ceiling-mounted acoustic panels further soften the interior with diffusion of sound and light.

Designed to support people and operations

A key feature of the office space is ready access to the adjacent warehouse space where inventory is managed. The building is designed to allow team members to seamlessly move between sales and order acceptance and packaging and delivery functions. Vertical-lift overhead doors expose shipping docks where pallets of the company’s mobile phone and Chromebook accessories are efficiently loaded for distribution.

A key feature of the office space is ready access to the adjacent warehouse space where inventory is managed. The building is designed to allow team members to seamlessly move between sales and order acceptance and packaging and delivery functions. Vertical-lift overhead doors expose shipping docks where pallets of the company’s mobile phone and Chromebook accessories are efficiently loaded for distribution.

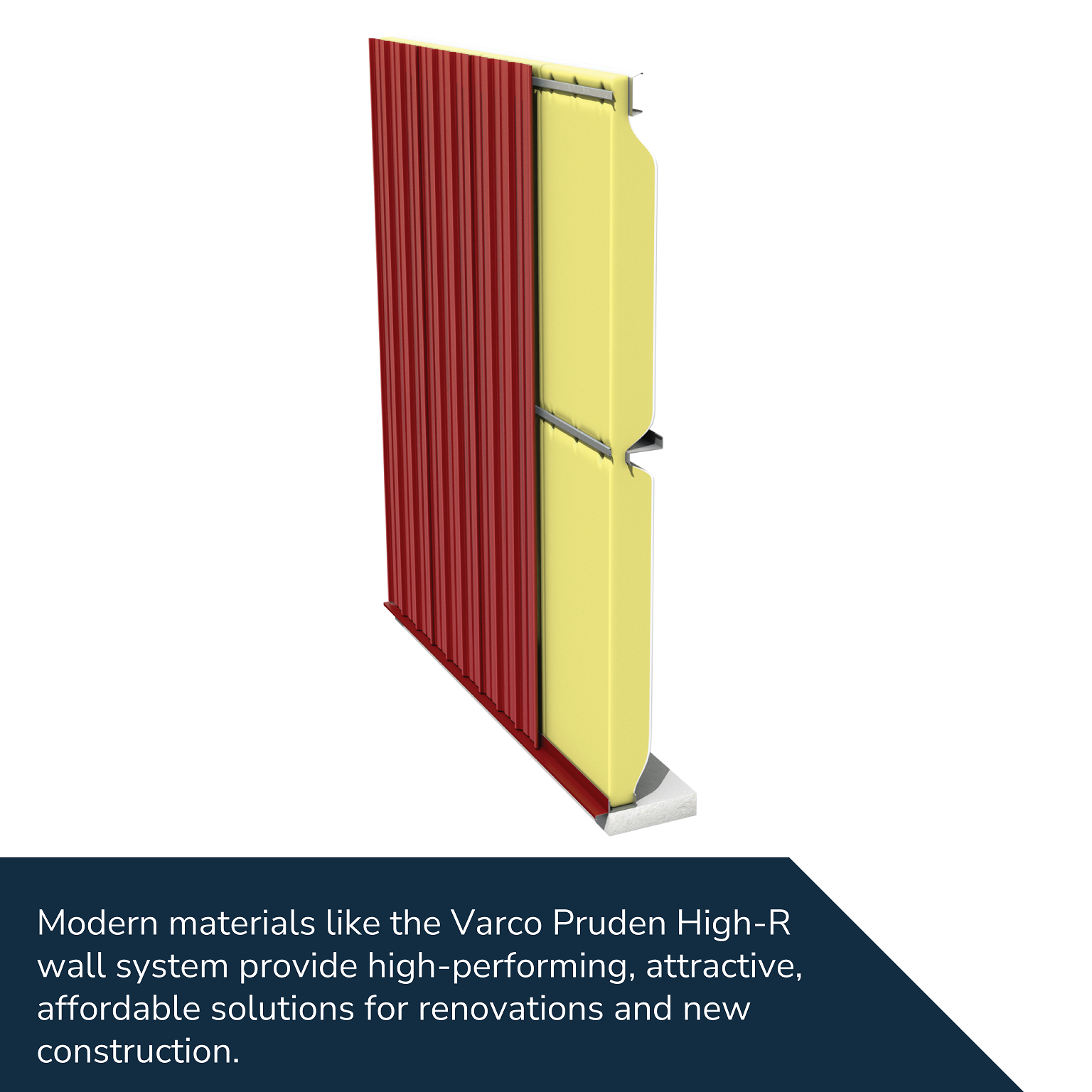

Outside, the structure is welcoming and functional. The entire metal building is wrapped with 3” insulated Varco Pruden metal panels making it low maintenance and highly efficient. Employees and visitors are greeted by contrasting entryways with canopies and masonry insets. Banks of floor-to-ceiling windows deliver natural light to the interior and visual flow to the exterior.

6 months after moving into their new building, the client has expanded its team and inventory to achieve growth goals and has diversified their revenue by leasing a portion of the new property.

Top honors in the Office Building category

“We didn’t set out to win an award with this project, but it’s great to be recognized. We always work to deliver a building that solves problems and creates opportunities for our customers’ business operations. In partnership with PURE Architects, we certainly accomplished that goal for Mobile Defenders and eduParts” says Doug Ritz, VP of Project Management & Pre-Construction at Veneklasen Construction.

“We didn’t set out to win an award with this project, but it’s great to be recognized. We always work to deliver a building that solves problems and creates opportunities for our customers’ business operations. In partnership with PURE Architects, we certainly accomplished that goal for Mobile Defenders and eduParts” says Doug Ritz, VP of Project Management & Pre-Construction at Veneklasen Construction.

Note: Since the building opened in October 2022, the Mobile Defenders brand has been sold to Virginia-based Mobile Sentrix. The EduParts division continues full operations from the new building.

Want to read more articles like this one? Sign up for our quarterly newsletter!

Veneklasen Construction is always looking for ways to leverage our capabilities for the good of the community. We’ve been helping local companies grow their businesses for nearly 50 years – and for the past 20 years, our development division has been carefully crafting rental housing options that boost West Michigan residents' quality of life.

Jami Buth, Veneklasen’s Director of Commercial Real Estate shares how the multi-family and mixed-use development business has evolved. “In the beginning, we pursued development projects to help build the construction company. Today, Veneklasen Development is a key part of our growth strategy and a valuable partner for municipalities dealing with housing shortages.”

Jami Buth, Veneklasen’s Director of Commercial Real Estate shares how the multi-family and mixed-use development business has evolved. “In the beginning, we pursued development projects to help build the construction company. Today, Veneklasen Development is a key part of our growth strategy and a valuable partner for municipalities dealing with housing shortages.”

Focused on solutions for West Michigan’s housing supply issues

Housing shortages are at a critical level. Kent and Ottawa counties grew by 90,000 residents from 2010 to 2021.1 The pandemic work-from-home trend further altered the housing landscape causing prices to surge and occupancy rates to explode to nearly 98% across the two-county region.2

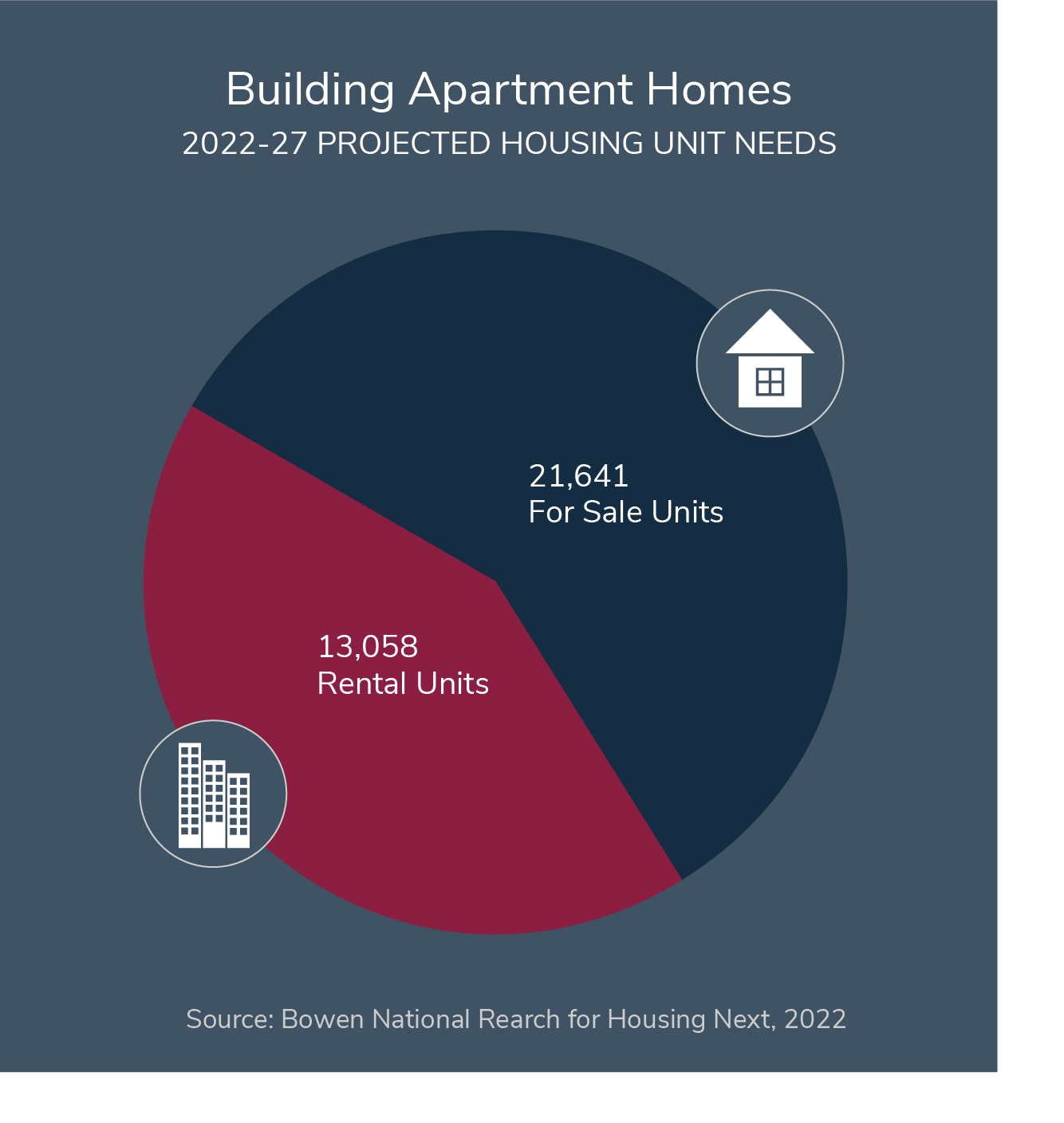

Housing Next, a Holland-based non-profit that exists to “identify, promote and foster quality housing for all” underscores the need to expand access to affordable housing for people at all income levels. The housingnext.org homepage states, “Communities that have enough housing at all price points provide greater economic stability, better health and greater access to quality education for all residents.” Research conducted in partnership with Housing Next concluded that 34,699 new housing units need to be constructed in Kent and Ottawa Counties by 2027 to address West Michigan’s persistent housing supply issue.3

Veneklasen Development is initiating projects that are part of the solution. “Our development focus is on tertiary markets across west and northern Michigan.” says CEO Chris Veneklasen. “These small to mid-size markets with populations of 2,000 to 10,000 residents have unique needs that we’re focused on filling.”

Housing shortages are at a critical level. Kent and Ottawa counties grew by 90,000 residents from 2010 to 2021.1 The pandemic work-from-home trend further altered the housing landscape causing prices to surge and occupancy rates to explode to nearly 98% across the two-county region.2

Housing Next, a Holland-based non-profit that exists to “identify, promote and foster quality housing for all” underscores the need to expand access to affordable housing for people at all income levels. The housingnext.org homepage states, “Communities that have enough housing at all price points provide greater economic stability, better health and greater access to quality education for all residents.” Research conducted in partnership with Housing Next concluded that 34,699 new housing units need to be constructed in Kent and Ottawa Counties by 2027 to address West Michigan’s persistent housing supply issue.3

Veneklasen Development is initiating projects that are part of the solution. “Our development focus is on tertiary markets across west and northern Michigan.” says CEO Chris Veneklasen. “These small to mid-size markets with populations of 2,000 to 10,000 residents have unique needs that we’re focused on filling.”

Placemaking creates balance and quality of life

New market rate apartments and mixed-use commercial buildings are reinvigorating these downtown areas. Pending projects in Whitehall and Spring Lake will do the same by providing quality, comfortable housing for middle-income residents plus spaces for restaurants and other commercial tenants.

The resulting balance is changing the experience of living in these small towns. Residential buildings bring customers to downtown businesses. When residents have access to services right in their neighborhood a special, symbiotic quality of life is created for everyone. “We’re seeing these communities benefit from our partnership and strategic placemaking activities. They have established industrial centers but lack housing. We’re helping them find a better balance. We’re very good at listening and translating a community’s ideas into a viable plan that suits all parties.” says Buth.

New market rate apartments and mixed-use commercial buildings are reinvigorating these downtown areas. Pending projects in Whitehall and Spring Lake will do the same by providing quality, comfortable housing for middle-income residents plus spaces for restaurants and other commercial tenants.

The resulting balance is changing the experience of living in these small towns. Residential buildings bring customers to downtown businesses. When residents have access to services right in their neighborhood a special, symbiotic quality of life is created for everyone. “We’re seeing these communities benefit from our partnership and strategic placemaking activities. They have established industrial centers but lack housing. We’re helping them find a better balance. We’re very good at listening and translating a community’s ideas into a viable plan that suits all parties.” says Buth.

Well-equipped to make a difference

The same team and equipment are used for both the development and general contractor divisions, but that’s about where the similarities end. In addition to performing as general contractor, we’re performing additional consultative roles:- Identifying property opportunities

- Working with city government to understand their vision for a property

- Researching financial scenarios

- Securing investor, bank, municipality, and State of Michigan funding

- Overcoming site constraints like parking and traffic flow

- Drawing up plans for a development that will serve all interests

Partners in creating strong communities

Once the construction of a property is complete, our role shifts. We stay engaged to perform facility maintenance defined under our warranty. We monitor the operations and rental occupancy of the new entity to be sure the business plan is performing optimally. In the current tight housing market, new residential units are typically leased as soon as they become available. Even so, professional property management and marketing are critical to strong communities. Therefore, we trust the experts at KMG Prestige Properties for ongoing leasing and property management services. Buth shares stories of two projects that illustrate the developer’s community commitment:- “The owner of the farmland that was purchased to build the Springhill Commerce Park envisioned it supporting West Michigan’s Christian School system. We were able to honor the owner’s intention for the legacy of the land, by bringing HeadStart Learning Center in as a tenant.”

- “The South Haven Center has really improved the downtown district. The first-floor commercial tenants bring value to the town, the residents are very happy and bring year-round patrons to downtown businesses.

“We’re selective about the projects we initiate, choosing the right community, the right piece of land, and the right partners to yield long-term and sustainable benefits.”

– Chris Veneklasen, CEOWant to read more articles like this one? Sign up for our quarterly newsletter!

The skilled trades workforce is aging, and there's a shortage of new talent to fill the gap. While many industries are feeling a shortage of workers, for the skilled trades vital to the construction industry the need is even more dire.

According to the Associated Builders and Contractors (ABC) in 2023 the construction industry needs to hire over 500,000 new workers in addition to the normal hiring pace of the overall economy. With such a vast construction workforce gap to bridge, what is the industry doing to meet that need?Construction Workforce Challenges

To diagnose any problem, one must search for the root cause. While the labor market is complex and no one factor can fully explain a shortage, there are several trends in the construction industry that are certainly contributing to the lack of skilled workers.

To diagnose any problem, one must search for the root cause. While the labor market is complex and no one factor can fully explain a shortage, there are several trends in the construction industry that are certainly contributing to the lack of skilled workers.

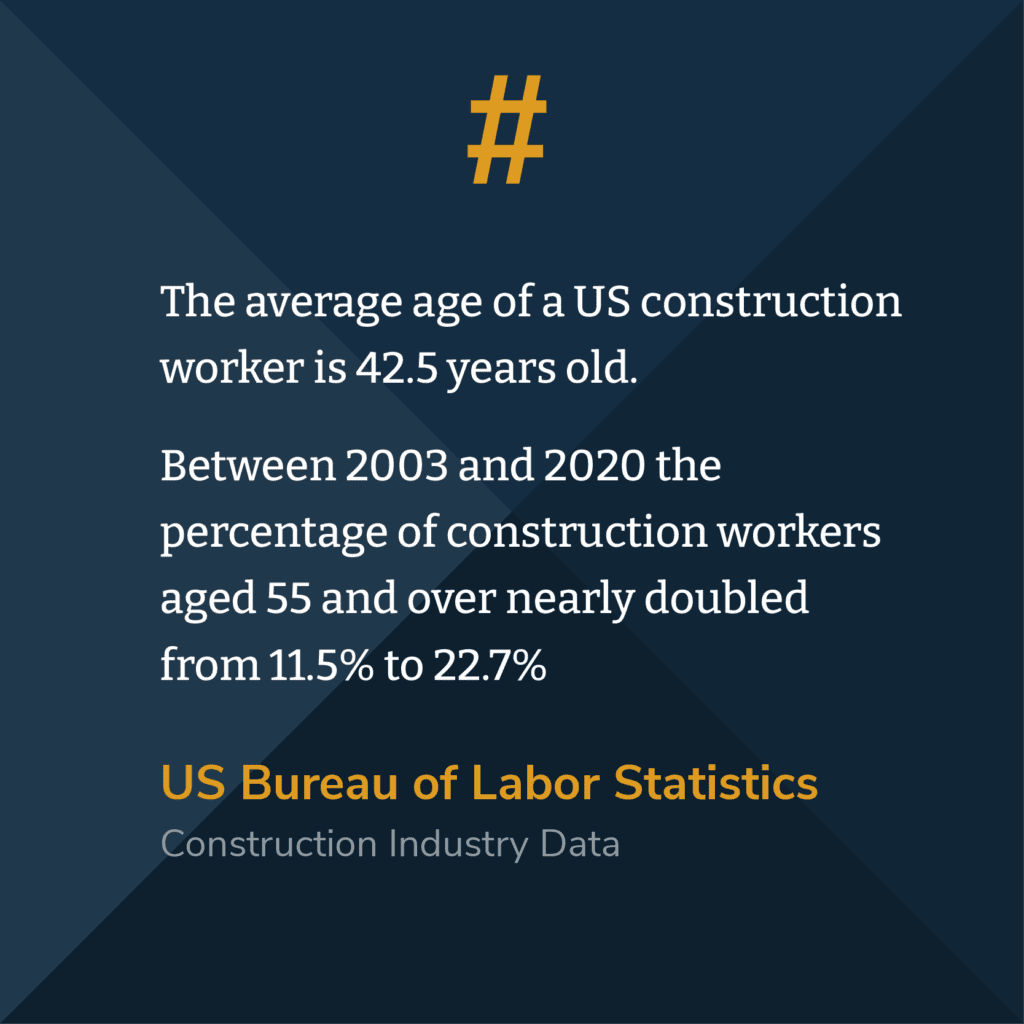

One of the biggest issues is that the most experienced members in the trades are retiring and no one is taking their place. According to the Bureau of Labor Statistics the average age of a construction worker is 42.5 years old and between 2003 and 2020 the percentage of construction workers aged 55 and over nearly doubled from 11.5% to 22.7%. Young people simply aren’t entering construction at sustainable rate of replacement.

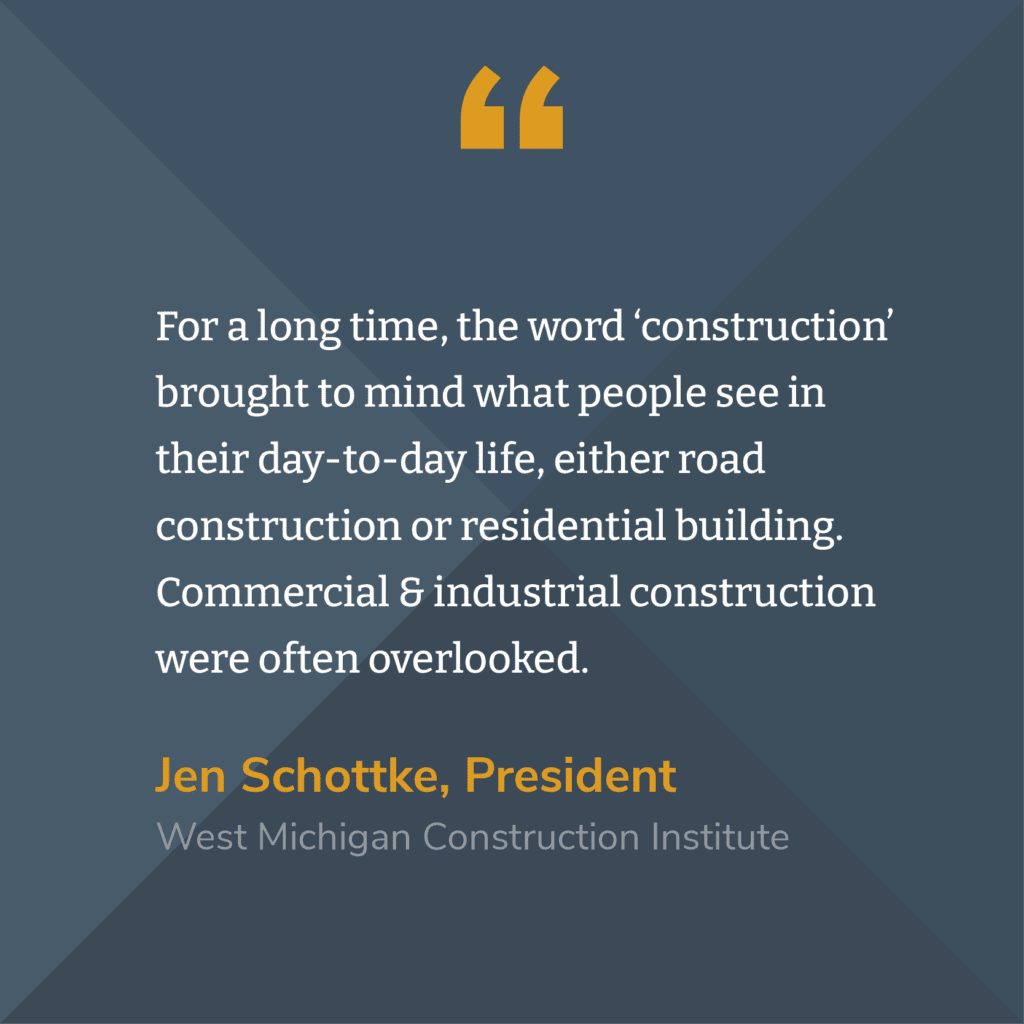

Organizations like the West Michigan Construction Institute (WMCI) are helping to address this problem by providing a pathway for those seeking to enter the commercial construction industry. They partner with schools, employers, and individuals to provide training, knowledge, and certifications that can lead to a meaningful and well-paying career in commercial construction. Jen Schottke, President of WMCI, related that she sees a wider cultural perception of the trades may be preventing high-school and college age individuals from entering the construction workforce.

“For a long time, the word ‘construction’ brought to mind what people see in their day-to-day life, either road construction or residential building. Commercial & industrial construction were often overlooked. In addition, construction jobs were seen as low skill and low pay. Thankfully in the past decade or so the construction industry has recognized the need to address this perception and has begun to significantly turn it around,” she said.

In addition, the fact that skilled construction workers are in high demand causes a tension that employers face between hiring experienced workers and spending time to invest in apprenticing and training new workers. While WMCI and organizations like it are positioned as a training and knowledge resource for employers, Schottke reiterates that, “Making the time for training and apprenticeships must be a corporate culture decision. There needs to be a recognition that there may be some slowdowns but that you will make it up in the long term through the investment made in talent development.”

What is the Client Impact?

One of the most obvious results of such a workforce shortage is that project timelines can start to get longer. With fewer skilled workers available, subcontractors may be stretched thin across multiple projects which can cause delays. This same lack of labor can also increase costs as the demand for construction services exceeds the available supply. Clients might also find it challenging to locate reputable contractors with available capacity during a workforce shortage. Skilled trades employees may feel pressure to rush their work, work longer hours, or make other concessions on the job site which could potentially lead to a decrease in overall performance. Workforce shortages can impact ancillary industries and supplies as well, causing common construction materials and supplies to become harder to get and more costly.Perceptions are Slowly Shifting

One of the ways that the industry is hoping to reduce the shortage of workers is by dispelling the myth that the skilled trades are low paying. While wages will always vary based on location and experience, the trades often pay better than people might imagine. Young people should also consider that many careers in the trades start off with apprenticeship programs where you are being paid while you learn. This can mean achieving a better financial position earlier in their career.

Shifting ideas about what a long-term career looks like also have had an impact. Many young people are looking outside of the college-degree-into-office-job pathway as college has become increasingly expensive. In the 20 years between 2000 and 2020 the average cost of tuition rose 69%. Instead of taking out student loans these individuals are stepping right into the workforce.

One of the ways that the industry is hoping to reduce the shortage of workers is by dispelling the myth that the skilled trades are low paying. While wages will always vary based on location and experience, the trades often pay better than people might imagine. Young people should also consider that many careers in the trades start off with apprenticeship programs where you are being paid while you learn. This can mean achieving a better financial position earlier in their career.

Shifting ideas about what a long-term career looks like also have had an impact. Many young people are looking outside of the college-degree-into-office-job pathway as college has become increasingly expensive. In the 20 years between 2000 and 2020 the average cost of tuition rose 69%. Instead of taking out student loans these individuals are stepping right into the workforce.

Diversifying the Construction Workforce

Along with the US workforce in general, the construction industry has started to recognize the need to recruit more women and minority workers. Women only accounted for 10.9% of the 11 million people employed in the construction industry in 2022, and Black or African Americans only accounted for about 6.7% of that total. These figures indicate a large, underutilized pool of talent. Organizations like the ACE (Architecture, Construction, Engineering) Mentor Program are helping to tap into this talent with after school programs, internships, and one-on-one guidance with industry professionals – all with the goal of attracting students into pursuing careers in one of those industries. The majority of ACE students (69%) come from minority backgrounds and over 40% of their students are female.Veneklasen’s Contribution

Being a construction employer, Veneklasen Construction bears the responsibility of training, supporting, and recruiting workers into the industry. Ensuring a safe working environment for our employees is one of our key priorities as well as a core value. By focusing on safety, we create an internal culture that boosts employee morale, improves retention, and gives confidence to our employees that they have a place to grow a long-term career.

Being a construction employer, Veneklasen Construction bears the responsibility of training, supporting, and recruiting workers into the industry. Ensuring a safe working environment for our employees is one of our key priorities as well as a core value. By focusing on safety, we create an internal culture that boosts employee morale, improves retention, and gives confidence to our employees that they have a place to grow a long-term career.

A long-term career at Veneklasen is also made possible by providing training in new areas of work, giving people opportunities for advancement and to take on new responsibilities. We are also currently expanding our recruiting efforts to include more women and minority candidates and evaluate our policies and procedures to promote a more diverse and inclusive workplace. These policies reinforce Veneklasen’s core value of “Integrity” which means that we do the right thing, always. This, in turn, influences our ability to hire good people and keep them on the team.

Veneklasen also encourages young people to become more familiar with the hands-on work of the trades. We host interns every summer from Ferris State University’s top-notch Construction Management program and give them field experience working with our Steel and Carpentry teams and helping manage active projects. During the summer of 2023, Brayden, an intern at Veneklasen, expressed his perspective on choosing a career in construction: "I didn't want to be confined to an office all day. Construction offers me the chance to stay active, meet new people, and make a tangible impact using both my mind and my hands."

Even younger students have the opportunity to gain exposure to the industry and learn about the construction process through events like WMCI’s Middle School Summer Construction Camp. This camp, put on by WMCI in partnership with construction employers around West Michigan including Veneklasen Construction, introduces students grades 6-8 to trades such as steel erection, welding, concrete, carpentry, painting and more. The hope is that they will not only have a great time but also discover an otherwise unknown passion for building and creating.

The workforce problem is complex, but we believe that we and other organizations are taking steps in the right direction. Ultimately, Veneklasen is trying to improve the construction industry by championing another of our core values: “Respect for People.” People are the difference makers for all industries and construction is no different. As the industry continues to evolve and adapt it is important that it provides a place where those people can have a clear career path, make a good living, and feel fulfilled in the work they do.

Want to read more articles like this one? Sign up for our quarterly newsletter!

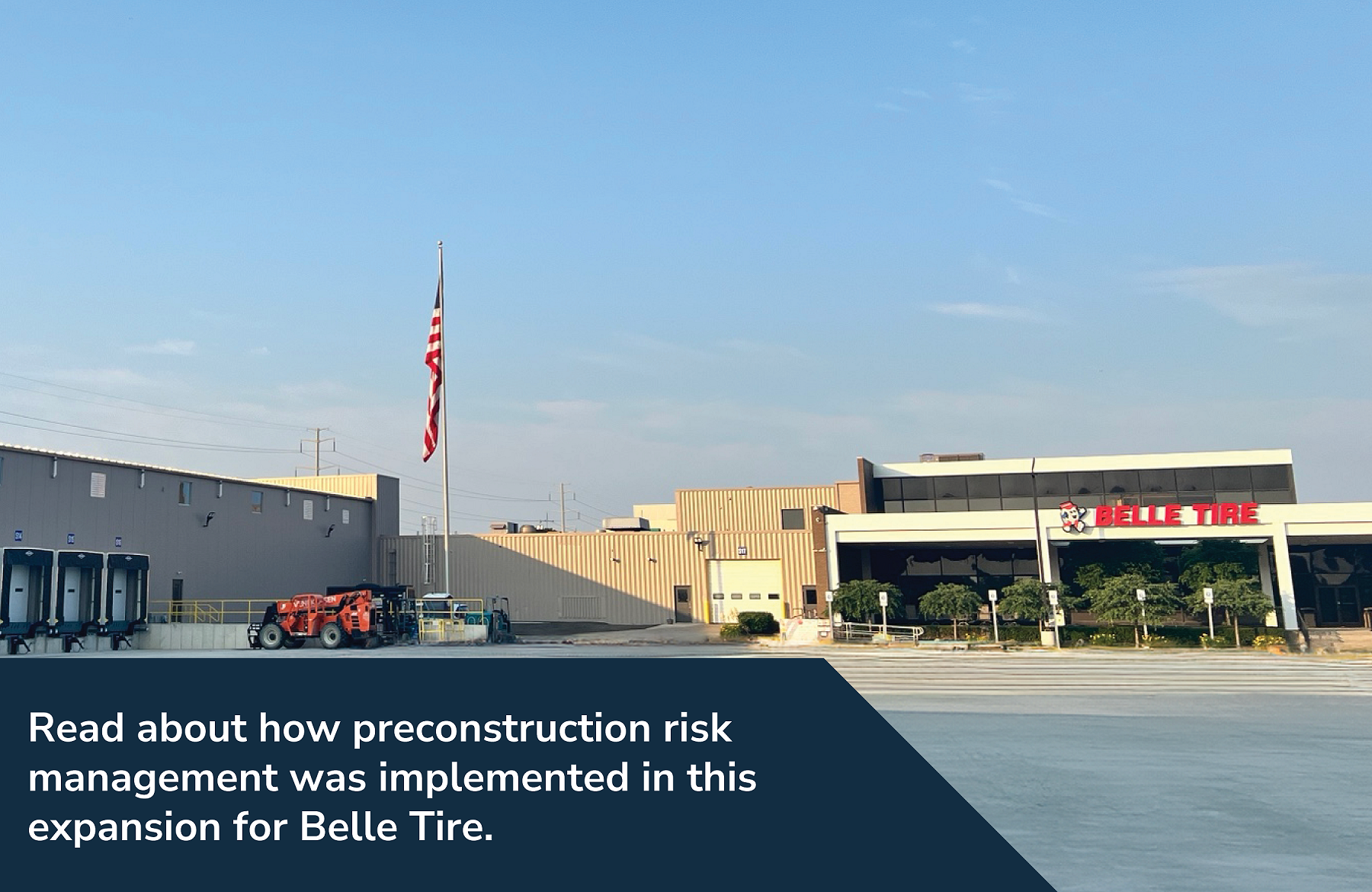

Launching a new business idea or expanding operations to meet demand is an exciting experience. But any business owner who’s faced this scenario will tell you it can also feel risky and intimidating.

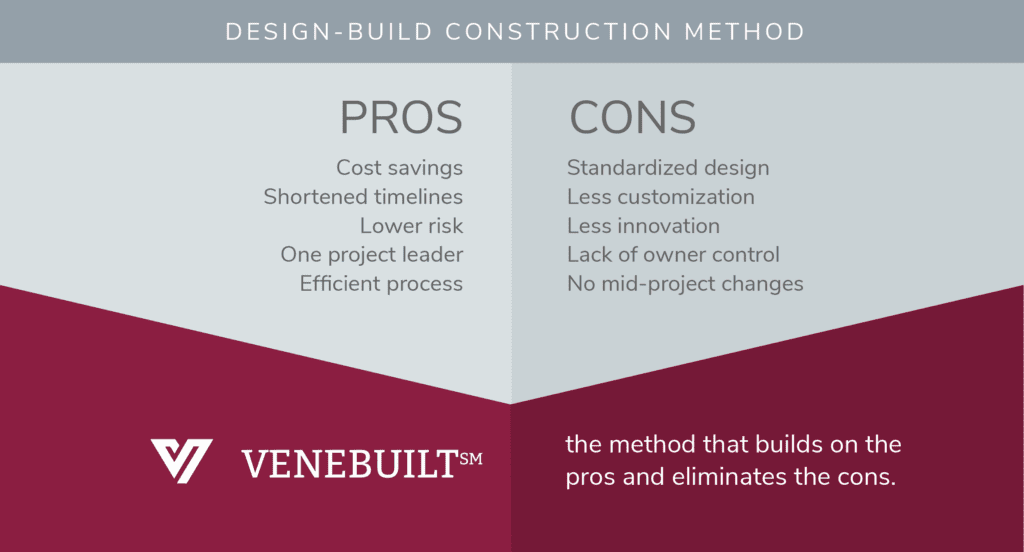

A design-build construction method may be your best bet for minimizing risk, but to achieve budget targets, you may need to make concessions in terms of quality. A special construction method we call VENEBUILTSM builds on the pros and eliminates the cons of traditional design-build construction.Design-Build PROS

We’ve been a design-build contractor for more than 40 years. We believe in a design-build approach to commercial construction because it’s been proven to be a cost effective and timeline-friendly solution - and who doesn’t value shorter timelines and smaller budgets?

We’ve been a design-build contractor for more than 40 years. We believe in a design-build approach to commercial construction because it’s been proven to be a cost effective and timeline-friendly solution - and who doesn’t value shorter timelines and smaller budgets?

A design-build approach centers around a single, empowered project leader – usually a general contractor – who has full scope knowledge of the construction process. This leader can facilitate efficient decision-making and manage overlapping timelines to streamline construction complexity, allowing projects to be completed quickly. The deep combined skillset and experience of a good design-build general contractor provides competency, predictability, and inherent risk management.

Design-Build CONS

The design phase is often condensed leading to a more standardized outcome. Because traditional design-build can limit the exploration of ideas and innovation, design customization is minimal. The building that results can lack the thoughtful design and quality construction that directly impact people and businesses for the long term.Traditional design-build can also put a client’s vision at risk. Managing a project for efficiency first can lead to a lack of control by the owner. If changes are needed mid-project to stay true to the owner’s vision, it can be disruptive and costly. A contractor who is primarily focused on keeping budget and timeline in-check may prefer to limit a client’s involvement after a project is underway.

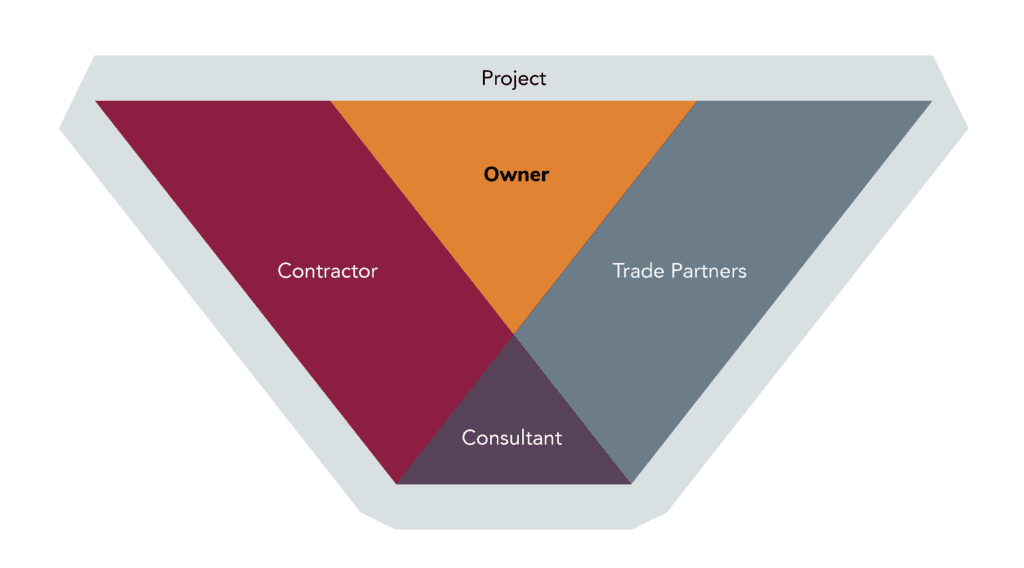

VENEBUILT is the work that comes before the work

Early-stage planning - before construction plans and estimates are developed – is critical. Digging into your project vision and exploring options early paves the way for efficiency, value, quality – and great design. Robert Andrus of Andrus Architecture describes how this stage works "Veneklasen brings together a collaborative team which includes the architect/engineer and other key partners. This team helps the owner to think through and fully vet their needs, desires, and aesthetics, enabling a quick and seamless generation of the necessary permit and construction documents.”

Early-stage planning - before construction plans and estimates are developed – is critical. Digging into your project vision and exploring options early paves the way for efficiency, value, quality – and great design. Robert Andrus of Andrus Architecture describes how this stage works "Veneklasen brings together a collaborative team which includes the architect/engineer and other key partners. This team helps the owner to think through and fully vet their needs, desires, and aesthetics, enabling a quick and seamless generation of the necessary permit and construction documents.”

At this point in the VENEBUILT method you are introduced to a team of experts like Andrus, each with a different specialty and an independent voice. Together, this group of architects, engineers, and construction pros will advise you on all aspects of your project and come together to recommend a construction plan that meets your budget, design, function, and business goals.

Whether you’re a construction veteran or exploring your first building project, this advisory team will guide you to an excellent outcome. Your Veneklasen team, which includes CEO Chris Veneklasen, knows the questions to ask. Chris Veneklasen explains how he approaches this first critical phase, “We know that a great outcome requires actively listening to a client’s needs and ideas. Our role at this stage is to provide leadership and to create a robust and responsive plan that integrates the ideas and solutions brought forward by a team of advisory partners that’s been assembled just for this project.”

VENEBUILT is a method and an attitude

Veneklasen didn’t solve the design-build pro/con dilemma overnight. “It required years of experience and humility to see that we could do better. It has also taken creativity and courage to break the mold.” Says Doug Ritz, Veneklasen VP of Project Management and Pre-Construction. Chris Veneklasen adds “VENEBUILT isn’t just an altered process, it’s a way of serving customers that results from the unique way we run our business and treat our people. Our core values of respect, integrity, passion, safety, and superior service have guided our development of the VENEBUILT model.”

Veneklasen didn’t solve the design-build pro/con dilemma overnight. “It required years of experience and humility to see that we could do better. It has also taken creativity and courage to break the mold.” Says Doug Ritz, Veneklasen VP of Project Management and Pre-Construction. Chris Veneklasen adds “VENEBUILT isn’t just an altered process, it’s a way of serving customers that results from the unique way we run our business and treat our people. Our core values of respect, integrity, passion, safety, and superior service have guided our development of the VENEBUILT model.”

The company’s culture and dedication to always do the right thing is responsible for their strong relationships with dozens of sub-contractors and architecture and engineering partners. Mike Corby, Managing Partner at Integrated Architecture shares his firm’s experience, “I appreciate how they respect what everyone brings to a project, especially on the design side. While I chuckle at Chris's cryptic sketches to help communicate his ideas, he really lets us do our jobs and is a great collaborator on projects.”

VENEBUILT uses a management approach focused on shared goals and empowerment.

Transparency between all partners, including the client, is facilitated by tech tools that create an openness to all aspects of a project. Veneklasen teams are specially trained in delivering the good news as well as confronting the challenges. When something doesn’t go as planned, the customer knows as soon as Veneklasen knows. When changes are needed, your project team is all-hands-on-deck to find solutions while doing what’s needed to maintain time and budget efficiencies.

Transparency between all partners, including the client, is facilitated by tech tools that create an openness to all aspects of a project. Veneklasen teams are specially trained in delivering the good news as well as confronting the challenges. When something doesn’t go as planned, the customer knows as soon as Veneklasen knows. When changes are needed, your project team is all-hands-on-deck to find solutions while doing what’s needed to maintain time and budget efficiencies.

The people you work with, combined with the processes they use, create a unique experience that can’t be replicated. Architect Mike Corby summarizes what it’s like to work with team Veneklasen like this: “They are a great group to work with! They work collaboratively and balance exceptional professionalism with enjoyable personalities. And they’re great communicators and leaders. They know how to bring good, tangible value ideas to projects, which is critical in today's construction climate.”

VENEBUILT creates a better experience

The VENEBUILT process is smart, but your process may be smarter, so flexibility is built in. Because Veneklasen leaders, project managers, and superintendents collaborate daily, adjusting to respond to special customer requests or react to hiccups like supply chain and engineering issues is simple and uncomplicated. “During the pandemic, it seems like every project had at least one supply chain issue. Lumber shortage one day, concrete the next. We use our existing collaboration process and good supplier relationships to quickly find solutions.” Says Nick Cadarette, Veneklasen Senior Project Manager .

“During the pandemic, it seems like every project had at least one supply chain issue. Lumber shortage one day, concrete the next. We use our existing collaboration process and good supplier relationships to quickly find solutions.” Says Nick Cadarette, Veneklasen Senior Project Manager .

No design-build experience is perfect, but the VENEBUILT method has succeeded in removing the flaws and enhancing the positives. A VENEBUILT project roadmap guides a series of processes that have been deliberately designed, continually improved upon, and customized for each project. All VENEBUILT projects are procedurally similar, so your team knows exactly what to expect. As Robert Andrus sees it “The VENEBUILT approach is an efficient and linear process that streamlines the workflow, minimizes uncertainties, and maximizes client satisfaction.”

The outcome of a VENEBUILT experience is a better design-build project that achieves your construction and business goals and eliminates costly change orders after your project breaks ground. According to Chris Veneklasen, “VENEBUILT is what we mean when we say we’re dedicated to building it right.”

Want to learn more about VENEBUILT and how it can work for you?

To summarize what we’ve learned by building hundreds of PEMB for all kinds of clients, here's a list of top 5 reasons why a pre-engineered metal building may be your best construction option:

1. Completely customizable – inside and out.

Pre-engineered metal buildings can suit any specific situation. Start by working with your architect or the Veneklasen Construction design team to design a building with distinct physical space needs in mind. Interior building heights, load and code requirements, equipment and storage needs, even extreme weather conditions can be accommodated. View many Pre-engineered metal building examples in our project photo gallery.

Pre-engineered metal buildings can suit any specific situation. Start by working with your architect or the Veneklasen Construction design team to design a building with distinct physical space needs in mind. Interior building heights, load and code requirements, equipment and storage needs, even extreme weather conditions can be accommodated. View many Pre-engineered metal building examples in our project photo gallery.

Any aesthetic or functional request specified in your design is possible. Integrate complex architectural features and choose from a large selection of quality finishes to achieve unique building profiles like those in these examples.

Incorporate interior and exterior finishes like wood, stone, brick, block, glass, conventional steel, and other materials to achieve the look and experience you have in mind. Cost effective and environmentally friendly options such as tilt-up concrete and exterior insulation finishing systems (EIFS) are also an option.

2. A Veneklasen pre-engineered metal building is always the high quality, dependable, and practical choice.

Veneklasen is an authorized Varco Pruden builder. Varco Pruden structural components are dependable, low cost, and built to last. Their ongoing commitment to innovation makes them a best-in-class supplier of structural steel, wall, roof, and installation systems. In addition, Varco Pruden design, order, and delivery processes provide consistent customer experiences that deliver lower cost and quicker grand openings.

Veneklasen is an authorized Varco Pruden builder. Varco Pruden structural components are dependable, low cost, and built to last. Their ongoing commitment to innovation makes them a best-in-class supplier of structural steel, wall, roof, and installation systems. In addition, Varco Pruden design, order, and delivery processes provide consistent customer experiences that deliver lower cost and quicker grand openings.

While a Varco Pruden building is expected to be strong, low-maintenance, and built to last, a Veneklasen-constructed PEMB regularly exceeds client expectations. Veneklasen employs a highly trained steel team with years of experience erecting steel buildings. This investment in people and equipment optimizes control and increases flexibility. Veneklasen can build to complex specifications with maximum efficiency and safety, and minimum time and cost.

Veneklasen serves as a general contractor on many pre-engineered steel projects, and also as a steel subcontractor on projects across the Midwest and beyond. This vast experience coupled with proven processes yields consistently excellent results. When a client enters their new PEMB space for the first time, they are surprised and delighted by the perfectly tight joints, beautiful interior finishes, and quality exterior materials.

3. Among the most sustainable construction options

You may be surprised to learn that a pre-engineered metal building is one of the most earth-friendly construction options. Steel is non-toxic to produce, infinitely recyclable, and reusable. It offers future flexiblity for alterations and additions with minimal environmental impact.Varco Pruden’s insulated wall and roofing systems maintain optimal internal temperatures and naturally absorb sound and condensation, which means more comfort and lower energy bills. Accessory options like skylights and translucent panels further enhance energy efficiency. When you use pre-engineered metal building components, you're making a great choice that can help achieve LEED accreditation or other sustainability goals.

4. Suitable for any scope of commercial construction project

A PEMB can be the best option for new construction, renovation, or expansion of an existing facility. Inherent design flexibility means it can serve a range of building needs. The secure supply chain which limits price fluctuations keeps costs down and performance up compared to the broader construction industry. Whatever your facility improvement goals, there’s a smart steel centered solution:

A PEMB can be the best option for new construction, renovation, or expansion of an existing facility. Inherent design flexibility means it can serve a range of building needs. The secure supply chain which limits price fluctuations keeps costs down and performance up compared to the broader construction industry. Whatever your facility improvement goals, there’s a smart steel centered solution:

-

Launch or expand operations with a brand-new custom steel building of any size.

Build a steel pre-engineered building addition integrated into an existing facility to efficiently expand manufacturing, office, and warehouse space.

Renovate to improve appearance, function, and energy efficiency of an existing building with upgraded finishes, innovative steel replacement roofing, thermal-clad panels, and entry and window features.

5. Adaptable to any industry

All industries can benefit from a PEMB solution. The Veneklasen Construction team has erected custom steel buildings that now serve as schools, factories, retail stores, offices, car dealerships, warehouses, airport hangars, and more. One of our most recently completed projects is a high tech addition for Seneca Foods, pictured here.

All industries can benefit from a PEMB solution. The Veneklasen Construction team has erected custom steel buildings that now serve as schools, factories, retail stores, offices, car dealerships, warehouses, airport hangars, and more. One of our most recently completed projects is a high tech addition for Seneca Foods, pictured here.

Each finished building is different to suit the nature of the people and operations it houses. Some are one-story, others are multi-story. Specialized designs feature brick and glass exteriors, while utilitarian designs feature durable insulated metal panel exteriors. Some welcome people into comforting, professional interiors, others welcome workers into safe and efficient production facilities. All were built with quality, function, and efficiency in mind to serve the long-range needs of each enterprise.

Want to read more articles like this one? Sign up for our quarterly newsletter!

One of the major causes of the limited amount of land for commercial development is a lag in infrastructure, particularly in terms of water, sewer, and road access. As existing land within the Grand Rapids metro area becomes increasingly scarce, businesses must search further afield for suitable locations to undertake their facility construction.

Collaboration Amongst Communities

Addressing the challenge of industrial land scarcity in West Michigan requires a collaborative effort among communities. Local governments, businesses, and civic organizations need to work together to develop a unified vision for sustainable growth. Regional partnerships and shared resources can help alleviate infrastructure bottlenecks and ensure that industrial development is both efficient and environmentally responsible. By fostering a sense of shared purpose, West Michigan can continue to harness its entrepreneurial energy while mitigating the strains on its available resources.

Addressing the challenge of industrial land scarcity in West Michigan requires a collaborative effort among communities. Local governments, businesses, and civic organizations need to work together to develop a unified vision for sustainable growth. Regional partnerships and shared resources can help alleviate infrastructure bottlenecks and ensure that industrial development is both efficient and environmentally responsible. By fostering a sense of shared purpose, West Michigan can continue to harness its entrepreneurial energy while mitigating the strains on its available resources.

Smaller communities within West Michigan hold great potential as new industrial business sites if infrastructure challenges are effectively addressed. Modern and reliable infrastructure is indispensable for businesses as it reduces operational costs and enhances connectivity. When seen as an investment in the community, infrastructure development becomes a compelling avenue to foster business growth and opportunities.

Helping communities make those investments in their future is, therefore, an important priority. Infrastructure development that results in land for commercial development is not cheap. It will take goal alignment and effort from many concerned parties to increase the appeal of smaller communities to industrial developers and businesses.

Financial Incentives

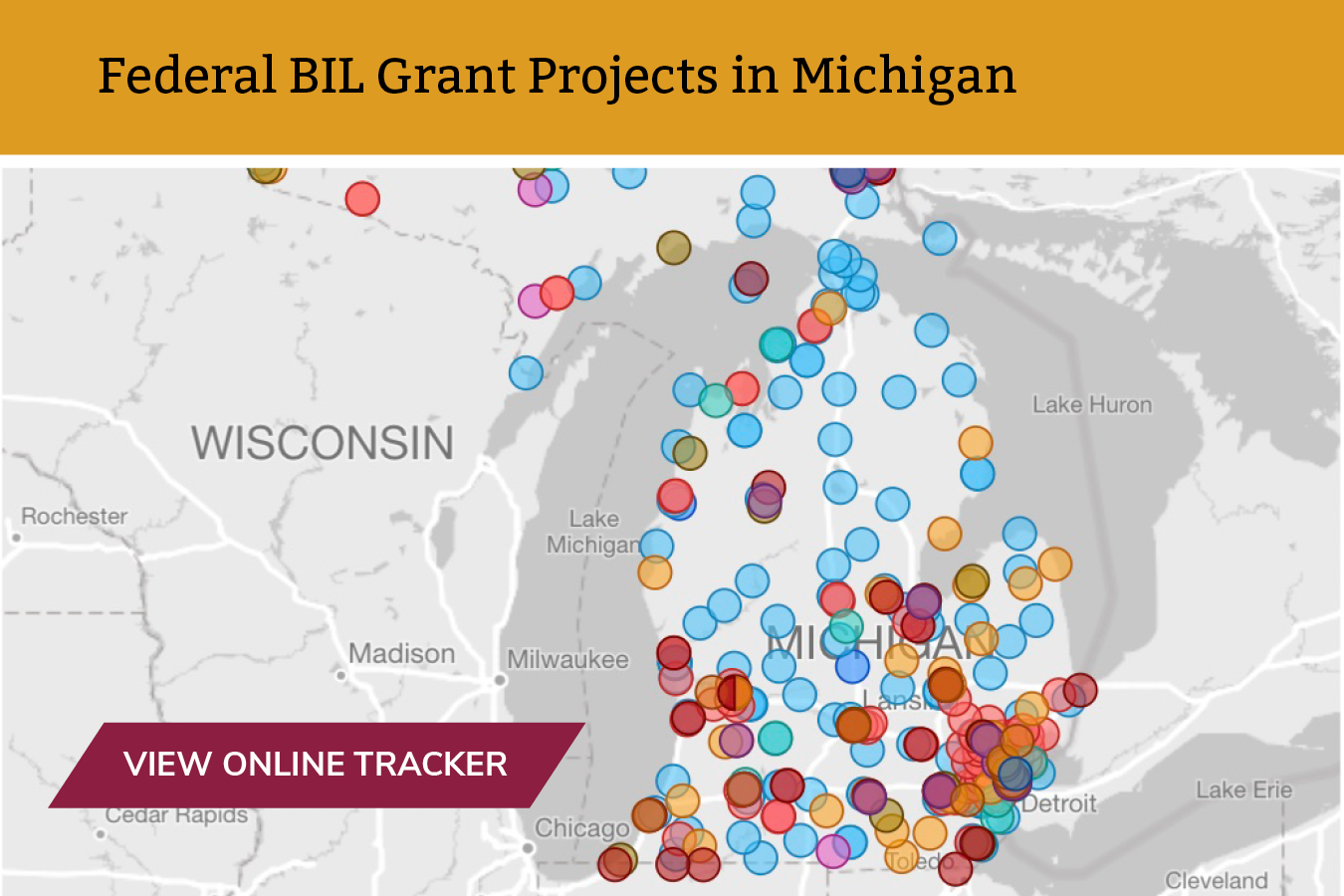

In recent years, the State of Michigan has been proactive in supporting developers and municipalities by offering incentives like brownfield redevelopment programs, tax benefits, and grants through organizations like the Michigan Economic Development Corporation (MEDC). Federal government grants made available by the Bipartisan Infrastructure Law (BIL) may also address the need for infrastructure to increase available land for commercial development. A online infrastructure investment tracker illustrates the nature and scope of current and pending investments. While most BIL funded projects benefit areas outside West Michigan, grants have been give to projects in Kent, Ottawa, and Muskegon Counties. These incentives serve as powerful attractors for developers seeking financial assistance in a market characterized by high land and construction costs.

In recent years, the State of Michigan has been proactive in supporting developers and municipalities by offering incentives like brownfield redevelopment programs, tax benefits, and grants through organizations like the Michigan Economic Development Corporation (MEDC). Federal government grants made available by the Bipartisan Infrastructure Law (BIL) may also address the need for infrastructure to increase available land for commercial development. A online infrastructure investment tracker illustrates the nature and scope of current and pending investments. While most BIL funded projects benefit areas outside West Michigan, grants have been give to projects in Kent, Ottawa, and Muskegon Counties. These incentives serve as powerful attractors for developers seeking financial assistance in a market characterized by high land and construction costs.

The brownfield redevelopment programs, for instance, encourage the revitalization of underutilized or contaminated sites, breathing new life into previously neglected areas. Tax benefits, on the other hand, offer a compelling financial advantage, allowing businesses to allocate resources to growth and innovation, thereby addressing the industrial land scarcity issue. By providing such incentives, the State of Michigan not only facilitates business growth but also enhances the overall economic resilience of West Michigan, positioning the region as an attractive destination for forward-looking entrepreneurs and industries.

Picking the Right Partner

When seeking a new site for building or development it is important to consider your partners carefully to ensure a great working relationship and shared goals. Your partners will play a critical role in the success of your project, so it is important to choose partners who you can communicate with effectively and who share your vision for the project. Veneklasen Construction is a partner that shares your values and brings extensive development experience to guide you through the process.Solving the industrial land scarcity problem

In summary, West Michigan's economic prospects remain promising, but industrial land scarcity presents a significant challenge to businesses and developers looking for land for commercial development. Addressing this issue through community collaboration, smart application of available incentives, and building long term partnerships is essential for sustaining the region's entrepreneurial spirit and ensuring a prosperous future. By working together and embracing innovative solutions, West Michigan can continue to thrive in the ever-changing business landscape.Want to read more articles like this one? Sign up for our quarterly newsletter!

Zeigler Subaru

Size: 36,000 SF

Size: 36,000 SF

This beautiful, brand new building is the new home of Zeigler Subaru of Merrillville. With a new name and new location but the same top quality service this location will offer the full stock of new Subaru models, all kinds of quality used vehicles, easy auto financing, and reliable parts and service in the Crown Point, Dyer, St. John, and Highland area.

Industrial Packhouse - Northern Michigan

Size: 21,587 SF

Size: 21,587 SF

For this unique Pre Engineered Metal Building project for an industrial client in Northern Michigan Veneklasen Construction used Insulated Metal Panels (IMPs) for both siding and roof. There were also features built into the PEMB design such as numerous windows, a truck dock canopy, and walking door canopies.

Seneca Foods

Size: 110,450 SF

Size: 110,450 SF

This project for long time client Seneca Foods consisted of a new ~100,000 SF pre-engineered warehouse addition, 7,700 SF connector tunnel, and 900 SF shipping office. It also included parking lot improvements.

Aldi - Allendale, MI

Size: 20,161 SF

Size: 20,161 SF

Veneklasen Construction has had the privilege of providing over 25 ALDI renovations over the past several years. The vast majority of these projects involved an addition to the building and a complete renovation to the entire store. However this project was a completely new building in Allendale, a growing college town just west of Grand Rapids, MI.

Tender Lawn Care

Size: 33,000 SF

Size: 33,000 SF

Tender Lawn Care has big plans for future growth in the greater Grands Rapids area. To help accommodate this growth, they hired Veneklasen Construction to build them a brand new, pre-engineered metal building (PEMB) to serve as an office and equipment storage facility. As a high-quality landscape management and snowplowing service provider to residential and commercial clients throughout West Michigan, Tender Lawn Care has invested in both equipment and people to build their successful business. This new building should serve them for many years to come!

Crown Lift Trucks - Schaumburg

Size: 13,504 SF

Size: 13,504 SF

Valued repeat customer Crown Lift Trucks has trusted Veneklasen Construction with projects in Michigan, Indiana, Ohio, and most recently with this office remodel in Schaumburg, Illinois.

Freight Distribution Facility - DeForest, WI

Size: 44,238 SF

Size: 44,238 SF

This freight distribution facility is a brand new, 60 door cross dock facility.

View Our Project Page for more

Want to read more articles like this one? Sign up for our quarterly newsletter!

We sat down with Veneklasen Construction Steel Supervisor Clay Towns, a 40-year veteran of the steel building industry to talk about his start in the world of construction, what he’s learned over the course of his construction career, and how the industry overall has changed.

Q: How did you first come to work for Veneklasen Construction?A: I had recently been laid off and my roommate at the time suggested I go down and apply at a place called Commercial Products down on Olson Street. He said, “it’s a boring job but pays decent money.” When I got there the door was locked and the lights were off, so I went to the business next door instead and talked to the receptionist at the front desk and she had the owner, A.J. Veneklasen, come out. He asked a me a few questions like “Are you afraid of heights?” and “Can you work in the cold?” I told him it was no problem and he said he’d think about it and give me a call.

Q: So, you hadn’t heard of or seen Veneklasen Construction (or A.J. Veneklasen General Contractors as it was known then) before?

A: Nope, although when I told my wife (Who was my girlfriend at the time) about it she said that it might be Jana’s brother’s business. Jana was a player on a softball team that I coached, and my wife also played on. I don’t know if she put in a good word for me or what, but a couple weeks later I got a call to come on down and start work on Monday.

Q: Can you tell me a little bit about your journey from an entry level steel crew member to the Steel Supervisor position?

A: It really is a story of putting in the effort. I worked hard and did anything and everything that was asked of me. I was the first person there in the morning and was always pushing the guys to get the work done on time. I took plans home and learned the blueprints. After two years I was promoted to Steel Foreman and eventually Steel Supervisor about 20 years ago. My wife was a huge support during this time and made a lot of sacrifices for us by watching our kids and taking on things so that I could put in extra hours and attention to my job so I am definitely thankful to her for that.

Q: What’s the best part of your job?

A: I think seeing the finished products of my work. My family gets sick of me saying “I built that building.” We go down the freeway and I’ll point them out “I did that one! Did that other one too!” I also love seeing the guys under me grow in their careers and find success as well. Even if they’ve moved on to other things or companies, I still see them from time to time and I feel like they appreciate what I was able to give them and teach them. That’s very rewarding.

Q: How has the construction industry changed in the 40 years that you’ve worked with Veneklasen Construction?

A: The equipment that we use has changed quite a bit. I started out with an Allis Chalmers forklift that had 21 feet of reach straight up. Now they’ve got SkyTraks that can shoot out and up. The buildings are also getting bigger and taller, which can make construction more challenging. Another big change over the years has been insulation. The r- values are going way up. It used to be that you’d need 6 inches of insulation on the roof and 4 in the walls but now they’re using IMPs or Simple Saver insulation.

Q: How about Veneklasen Construction itself?

A: Well, there is the size of the company. We started out with 6 guys in the field, and 3 or 4 in the office and now we’ve got over 60 people. We’ve also expanded the types of buildings we do as well. We’ve done sports complexes, industrial & manufacturing buildings, multi-family, and a lot more.

Q: What’s one of the most memorable projects that you’ve worked on over the years?

A: GAREAT Sports down in Ohio (now called the SPIRE Institute). Started that one in 2008 when times were bad. That one probably kept us in business at that time. We started off building an indoor soccer stadium and basketball court. Then we did a big building which was a 300-foot clear span for football practice. Then they did a third building where they imported a swimming pool from Italy. That was one of the first buildings we built with IMPs. I don’t know if they ever made it or not, but they were looking to get Olympic athletes training there eventually.

A: GAREAT Sports down in Ohio (now called the SPIRE Institute). Started that one in 2008 when times were bad. That one probably kept us in business at that time. We started off building an indoor soccer stadium and basketball court. Then we did a big building which was a 300-foot clear span for football practice. Then they did a third building where they imported a swimming pool from Italy. That was one of the first buildings we built with IMPs. I don’t know if they ever made it or not, but they were looking to get Olympic athletes training there eventually.

Q: Do you have any advice for those looking at the construction industry as a career?

A: If you’re energetic and want to learn it’s a great field to get into. It pays well especially if you’re there consistently every day and show that you’re reliable. Attendance is huge in my eyes if you want to be successful in a construction career.

Q: What do you wish for the steel crew and your other Veneklasen colleagues as they carry on doing the work you’ve done for 40 years?

A: Really just keeping up the quality of work that we’ve been known for all these years and continuing to stay safe on the jobsite. I want to see them succeed and being able to go home safely at the end of the day is obviously a big part of that.

Q: Now that you have 40 years of hindsight - is there anything you would’ve done differently during your construction career?

A: I would have asked for help more often. When I was younger, I thought I could do everything myself. Guys would say “You can’t carry that column over there!” And I’d respond, “Oh yeah?” then pick it up, put it on my shoulders, and walk it right over to where it needed to be. But I got two hip replacements out of doing stuff like that, so I definitely paid for it! Asking for help and leaning on my team members more would definitely be at the top of the list.

Q: Any parting words of wisdom for the management team at Veneklasen?

A: Keep pushing to achieve your goals but don’t grow so fast you lose the company culture you’ve built. Listen to the team out in the field and continue to set them up for success. Keep up with equipment and technology changes to keep everyone safe and increase efficiency and effectiveness.

Q: Finally, what are your plans for retirement?

A: Golf! I plan to do lots of golfing as well as traveling around the country. Nowhere specific in mind yet, but it will probably be to somewhere warm. My wife and I also want to see a lot of the national parks so we will spend some time doing that.

We want to thank Clay for his time and for the 40 years of hard work that he has put in at Veneklasen Construction. We wish him all the best and a happy retirement. He’s earned it!

Want to read more articles like this one? Sign up for our quarterly newsletter!

The “Dreaming Phase”

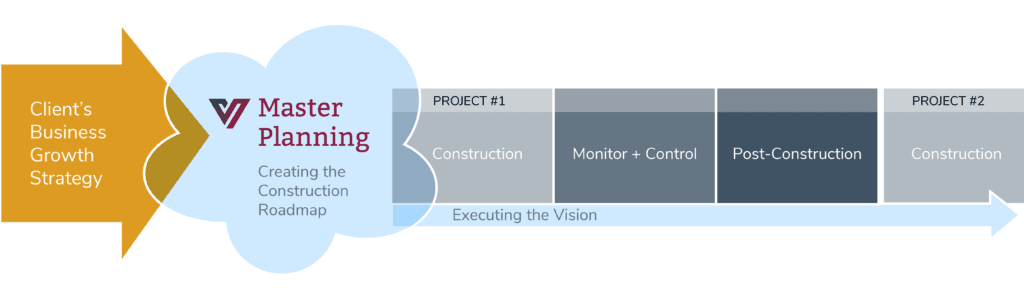

Envisioning possibilities is always the fun part. Like that stage of vacation planning when you’re picturing yourself on a pristine beach or in a picturesque village. Master planning and dreaming about new places is invigorating, but when you inevitably begin to think about the reality of your budget, timeline, and conflicting priorities your dreaming can come to a screeching halt. The same can happen when you begin envisioning how a new or expanded building can meet the needs of your growing business. The “dreaming phase” is important. It’s where your business goals, operational realities, and creativity combine to result in new opportunities. Rushing through the master planning phase to get straight to the details like zoning restrictions, site limitations, budget, etc. can unfortunately be the path to mediocrity and lost opportunities.Future-proof your investment with master planning

Master planning delivers a roadmap for executing your business growth strategy. It is the first and most important phase of the VENEBUILT construction process.

The comprehensive master planning work that’s a standard part of Veneklasen Construction’s VENEBUILT process allows you to fully develop your vision. This means you can break ground on a commercial construction project with confidence. It starts with direct collaboration between your leadership team and ours to transfer knowledge of your business goals, growth targets, and existing land and facilities. Next, we apply our expansive knowledge of commercial construction management to identify the path forward. The result is a strategic plan that helps you understand today’s reality as well as your property's future potential. In addition to construction excellence on your building project, you can expect these major outcomes from the master planning process:Minimized financial surprises

- Talking about your next move early can save time and money down the road. Informed decisions about how to approach a project in the short term will set you up for success in the future.

- New land is scarce and expensive. Master planning focuses on getting the most out of your existing site.

- A full review of what’s possible on your existing site gives you time to look for supplemental land or to consider other building options if the need is identified.

The scope of master planning

“People come to us with vacant land or maybe a couple acres on an existing site. They know WHY they need to expand their operation but need help with the what, the how - all the detail.” explains Doug Ritz, VP of Project Management and Pre-Construction at Veneklasen Construction. “We help them look years down the road at how their site and facility can expand to support their business goals.” Armed with knowledge of where a client wants to take their business, the Veneklasen team goes to work. “Really our entire team gets involved – project managers, estimators, designers, even Chris Veneklasen, our CEO.” says Ritz. “We actively listen and pool our collective experience to consider all the options and get creative to overcome roadblocks. For particularly complex projects we call on architecture and engineering partners whom we trust and respect.”Agapé Plastics – Thinking outside the pond

Agapé Plastics is a great example of the value of master planning. This West Michigan-based manufacturer of injection molded parts for the automotive, furniture, and other industries needed to expand operations to keep up with customer demand. A small pond on their site impeded the second of two planned expansions. Master planning work identified two viable scenarios:

Agapé Plastics is a great example of the value of master planning. This West Michigan-based manufacturer of injection molded parts for the automotive, furniture, and other industries needed to expand operations to keep up with customer demand. A small pond on their site impeded the second of two planned expansions. Master planning work identified two viable scenarios:

- Stand-alone building - Build a detached 54,000 SF building near the existing plant. This option would be simple to implement but would require the client to make inefficient operational changes.

- Expansion - Excavate the site to remove the pond, allowing expansion of the existing facility.

After Team Veneklasen sought and received approval from the US Department of Environmental Quality to move the pond, the expansion plan was selected. While more challenging, it was determined to be the smartest, most cost-effective option.

Dedicated to building it right.

“Our master planning work is emblematic of our brand promise; Dedicated to building it right. We leverage our team’s range of skills, knowledge, and perspectives to guide a client and help them fully understand their options because it always leads to better outcomes.” Explains Ritz.

Not every GC works this way, but it’s a proven best practice at Veneklasen Construction. Master planning allows customers to dream big, knowing that their partner is thinking about all the details.

“Our master planning work is emblematic of our brand promise; Dedicated to building it right. We leverage our team’s range of skills, knowledge, and perspectives to guide a client and help them fully understand their options because it always leads to better outcomes.” Explains Ritz.

Not every GC works this way, but it’s a proven best practice at Veneklasen Construction. Master planning allows customers to dream big, knowing that their partner is thinking about all the details.

Anatomy of a Master Plan

| 1. DISCOVERY PHASE Clearly defining the scope of the project and defining current and potential future needs, including its objectives, deliverables, timelines, and budget constraints |

2. FEASIBILITY STUDY Assessing the construction site to understanding its topography, soil conditions, and any potential challenges or constraints that may affect the project. In addition, evaluating the site’s maximum capacity for current and potential future project phases. |

| 3. REGULATORY COMPLIANCE Ensuring compliance with local building codes, regulations, and zoning requirements. Obtaining necessary permits and approvals for the construction. |

4. BUDGETING AND COST ESTIMATION Developing a detailed budget that includes all anticipated costs, such as materials, labor, equipment, permits, and any unforeseen expenses. |

| 5. SCHEDULING Creating a project schedule that outlines the sequence of tasks, milestones, and deadlines. This helps in tracking progress and ensuring timely completion. |

6. RESOURCE MANAGEMENT & SUBCONTRACTOR COORDINATION Coordinating the allocation of resources: labor, materials, and equipment, to optimize efficiency and productivity. Managing relationships with subcontractors. Ensuring their work aligns with the overall project plan. This involves hiring, scheduling, and overseeing subcontractors' activities. |

| 7. RISK MANAGEMENT Identifying potential risks and developing strategies to mitigate them. This may involve contingency planning for unexpected events that could impact the project. |

8. QUALITY CONTROL Implementing quality assurance measures to ensure that construction meets the specified standards and complies with relevant regulations. |

| 9. COMMUNICATION & COLLABORATION Facilitating effective communication among all stakeholders, including architects, engineers, subcontractors, and clients. Collaboration is essential for a successful construction project. |

10. CHANGE MANAGEMENT Handling changes to the project scope or schedule. Ensuring that any modifications are documented, approved, and implemented in a controlled manner. |

Want to talk with someone about master planning for your next project?

Two West Michigan buildings constructed this year by the general contractor Veneklasen Construction have been named to Varco Pruden’s 2024 Hall of Fame: Irish Boat Shop in Harbor Springs, MI and Tender Lawn Care in Grand Rapids, MI.

Varco Pruden’s highly competitive Hall of Fame Awards are presented annually to builders whose work reflects innovation and excellence through the integration of VP building systems, products, architectural appearance, end use, and design. Submissions include a range of industrial, commercial, retail, and municipal structures, and builders may submit multiple projects.

2024 Varco Pruden Hall of Fame Projects

Irish Boat Shop is a 15,250 SF retail location located in Harbor Springs, Michigan. Veneklasen Construction acted as the steel erector for this project and worked closely with designer Bluebird Day Architecture and Varco Pruden’s Conventional Steel Services to design and erect the steel to the client’s specifications. This close collaboration resulted in a beautiful and functional building that was recognized by Varco Pruden in the category of Conventional Steel Building.

Irish Boat Shop is a 15,250 SF retail location located in Harbor Springs, Michigan. Veneklasen Construction acted as the steel erector for this project and worked closely with designer Bluebird Day Architecture and Varco Pruden’s Conventional Steel Services to design and erect the steel to the client’s specifications. This close collaboration resulted in a beautiful and functional building that was recognized by Varco Pruden in the category of Conventional Steel Building.

Tender Lawn Care’s new building is a 33,696 square foot pre-engineered metal structure designed by architecture firm Ghafari Associates. The building houses the company’s offices and is used to store, clean, and maintain Tender Lawn Care’s vehicle fleet as well as other landscaping and snow removal equipment. Locating offices and important operational functions on one property is allowing the growing company to improve efficiencies and better serve their customers. This building earned Hall of Fame recognition in the Miscellaneous category.

Tender Lawn Care’s new building is a 33,696 square foot pre-engineered metal structure designed by architecture firm Ghafari Associates. The building houses the company’s offices and is used to store, clean, and maintain Tender Lawn Care’s vehicle fleet as well as other landscaping and snow removal equipment. Locating offices and important operational functions on one property is allowing the growing company to improve efficiencies and better serve their customers. This building earned Hall of Fame recognition in the Miscellaneous category.

Veneklasen Construction CEO Chris Veneklasen had this to say about the Hall of Fame awards: “We are immensely proud of these achievements and grateful for the opportunity to showcase the talent and dedication of our team on a national stage. Being recognized by Varco Pruden, a respected authority in the industry and a valued business partner, further validates our position as leaders in builders of conventional and pre-engineered metal buildings. These awards not only recognize the expertise of our team but also highlight our relentless pursuit of innovation and quality in every aspect of our work.”

About Veneklasen Construction

Veneklasen Construction has specialized in high-quality industrial, commercial, and multi-family, residential buildings since 1975. Using our experienced internal team and our VENEBUILT design-build delivery method, Veneklasen Construction adds value to each project throughout the entire construction process. Today, a people and relationship focus drives our growth. Prioritizing investment in our team and strategic leadership provides impactful client experiences and we are proud to be the general contractor of choice for many repeat customers, including Fortune 100 companies.About Varco Pruden Buildings

Varco Pruden Buildings is a division of BlueScope Buildings North America, Inc. Through advanced engineering and proprietary building products, Varco Pruden provides innovative steel building solutions worldwide for low-rise commercial and industrial applications – including offices, warehouses, schools, manufacturing and retail projects. Headquartered in Memphis, Tenn., the company markets its products through a network of nearly 1,000 authorized builders within the United States and Canada. For additional information, visit vp.com.Want to read more articles like this one? Sign up for our quarterly newsletter!

Even the most ambitious and stunning construction project can run into serious issues without a solid foundation – and that foundation starts with an accurate estimating process.

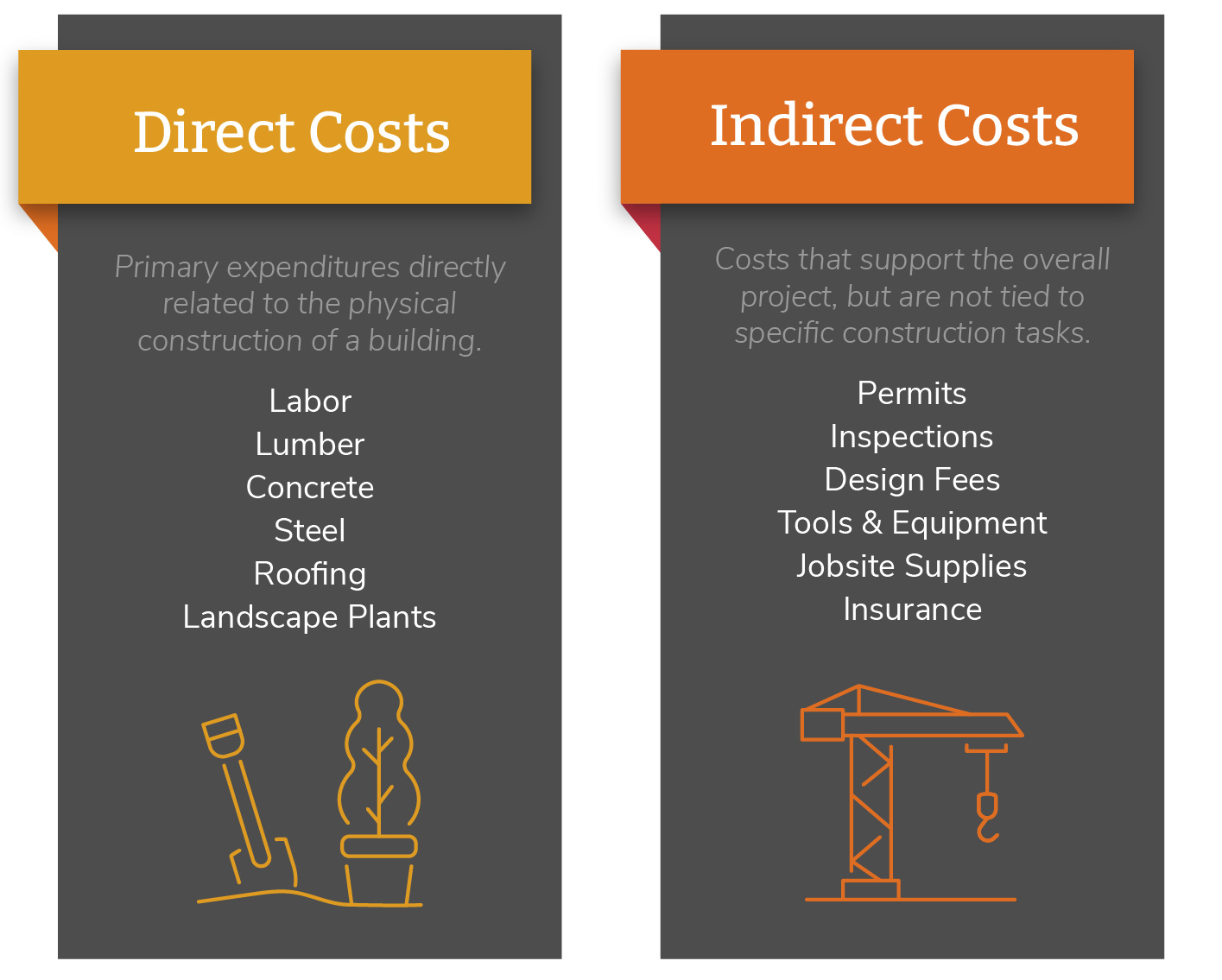

In construction, the estimating process forecasts the costs involved in a project. It accounts for direct costs like raw materials and labor and indirect costs like permits, inspections, and administration expenses. When being considered for a project, a general contractor (GC) will create an estimate, which represents the budget they believe is needed to complete the project.

In construction, the estimating process forecasts the costs involved in a project. It accounts for direct costs like raw materials and labor and indirect costs like permits, inspections, and administration expenses. When being considered for a project, a general contractor (GC) will create an estimate, which represents the budget they believe is needed to complete the project.

The estimating process is particularly important as it helps determine the contract price that the client and GC ultimately agree upon. Having an accurate estimate is crucial to keeping costs down, minimizing change orders, completing projects on time and on budget.

At Veneklasen Construction, our estimating department is led by Rob Miller, a 19-year employee and subject matter expert. Rob explains the importance of the estimating phase of a project: “Estimating as accurately as possible is important to both the general contractor and the client. The GC wants to be competitive while still being able to make a profit, while the client needs an accurate estimate to determine the feasibility of the project, their return on investment, and to secure financing from the bank or investors.”

How Its Done – Project Cost Estimation

The method and depth of a project estimate depends on where the project stands in its design phase.- For projects that are still just a concept or in the preliminary design stages, a general estimate can be put together based on the size and type of project. This estimate often uses historical data from past projects, industry trends, trade partner insights, and standard unit costs. These general estimates can be useful in determining if a project can move forward as is, or if design changes need to be incorporated to keep the project within the desired budget.

- Projects that are further along in the design process and are more certain to be moving forward, are at a stage where an in-depth estimate is needed. In addition to our in-house cost analysis, we solicit feedback from subcontractors and suppliers to validate current market costs and value add opportunities.

For each trade and element of a project an estimator will generally request at least 2 to 3 bids from subcontractors and suppliers so that they can ensure cost efficiencies are recognized and a competitive final price. This is where choosing a GC who maintains good working relationships with trade partners and subcontractors makes a significant difference. GCs who have these relationships are better able to analyze the pricing they receive and balance cost with quality of work.

Technology improves speed and accuracy

Like many industries, the field of construction is seeing the integration and innovation of artificial intelligence (AI) tools. These tools can analyze data and trends quickly, giving an estimator not only a larger pool of resources to draw from but speeding up the process of getting measurements and material costs. AI’s predictive capabilities can also consider factors such as material price changes, labor costs and availability, and more.

Like many industries, the field of construction is seeing the integration and innovation of artificial intelligence (AI) tools. These tools can analyze data and trends quickly, giving an estimator not only a larger pool of resources to draw from but speeding up the process of getting measurements and material costs. AI’s predictive capabilities can also consider factors such as material price changes, labor costs and availability, and more.